Many of you may be aware of the “Process Flow Diagram (PFD)” which is shown below. A PFD helps in mapping the entire manufacturing process responsible for the product. It maps the manufacturing process steps right from the receipt of raw material, till despatch. This PFD mapping helps to develop the PFMEA & Control plan. This PFD, PFMEA & Control Plan helps in improving the quality (effectiveness) & quantity (efficiency) of the component aiming for zero defects.

Similarly the “Business process flow diagram” or “business mapping” is

vital in improving the effectiveness (quality) & efficiency (profit) of the

business. In many of my articles I have quoted the importance of “the owner

with his team needs to build a perfect business map & review this frequently”.

This article will help in assisting business owners to build a strong “business

process flow diagram” or business map. Such a “Business process flow diagram”

is common for all businesses, it can be done by school, college, hospital, bus

stop (Koyambedu CMBT bus stand is an ISO certified bus stand), hospitals etc.

To build a business map, the owner & his team must have a thorough

understanding about the terms “Activity”, “Process”, “System” &

“Procedure”. See the slide shown below that defines activity, process, system

& procedure. As the sequence suggests, without defining activities

involved, processes cannot be defined properly. Without defining activities

& processes, systems (qms, ems, ohsas etc) cannot be defined properly.

Without defining systems properly, procedures cannot be built perfectly. Once

this understanding is clear the owner & his team can proceed further in

building a self-sustaining, continually improving processes which helps

businesses to reach TQM levels.

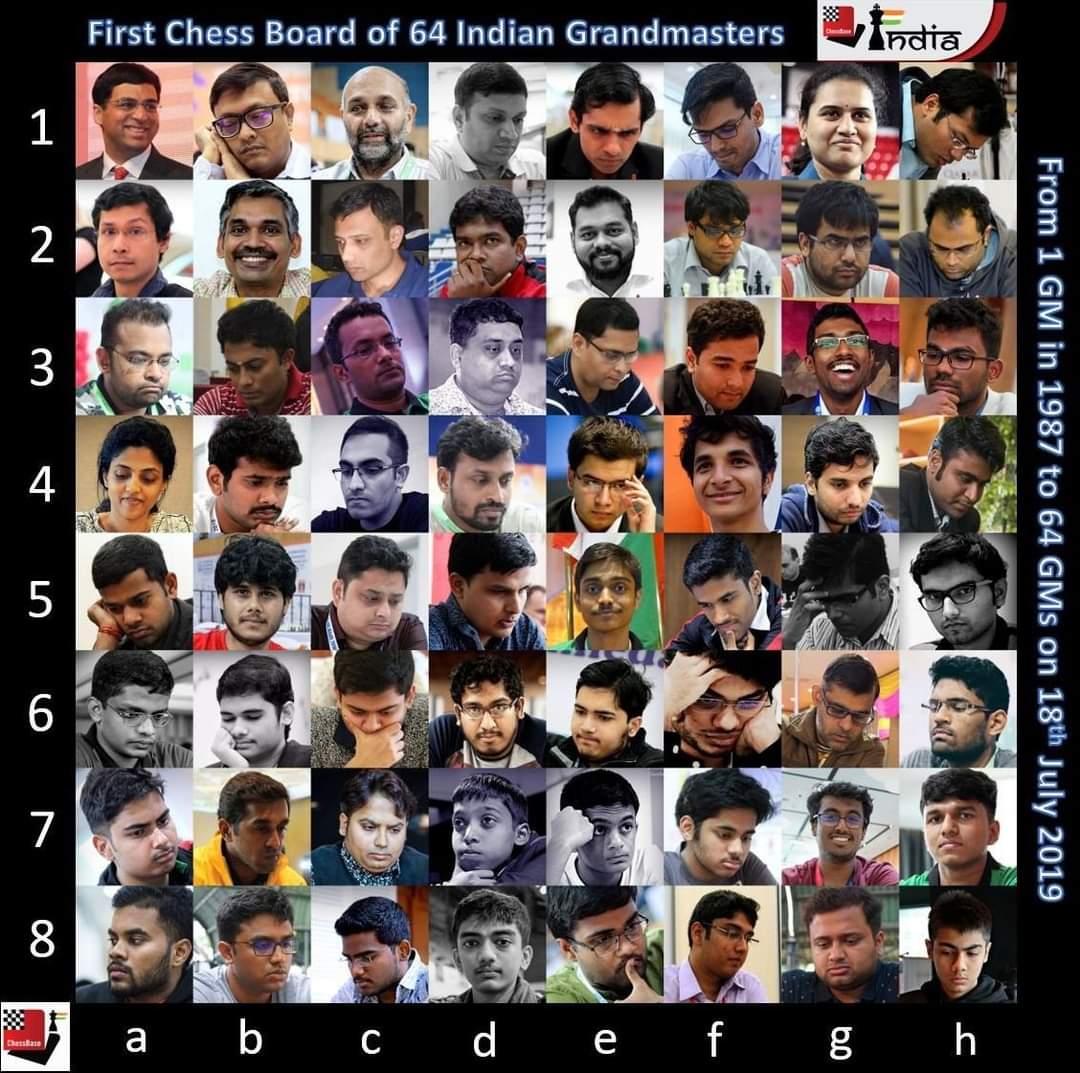

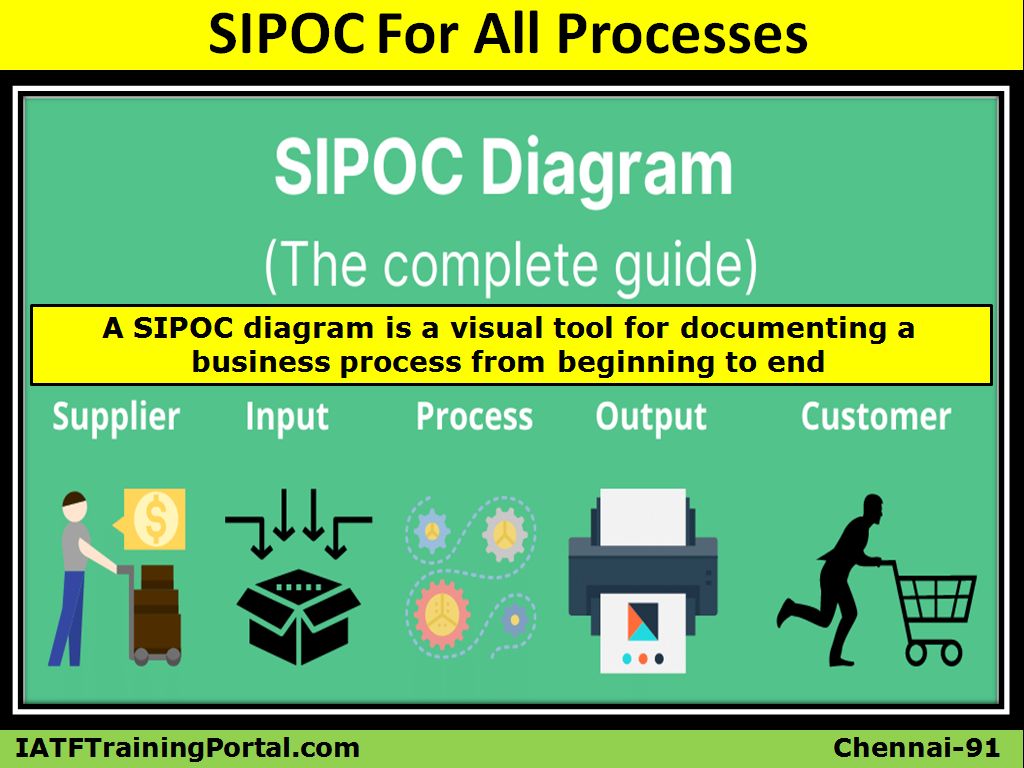

SIPOC which is a quick summary of processes (like a ready reckoner)

needs to be understood first, a sample SIPOC is shown below. When all the

processes or departments related SIPOCs are compiled perfectly by adding more

spice to SIPOCs like covering 7M conditions, “Process measures” or “KPI” or

“Process Objectives” etc., it serves as a perfect tool to monitor & control

all the processes (or departments) to bring them to Six Sigma & TQM levels.

Such spicy SIPOC can be called a “Process Analysis Sheet” or “High Level Process

Map” etc.

To help the business community in building perfect SIPOCs / Process

Analysis Sheets, I will be providing samples of around 23 department-wise

SIPOCs / Process analysis sheets in this article. This will help everyone to

understand the concepts as well implement SIPOCs strongly in their existing

businesses.

In building “business process flow diagrams”, mapping the “Sequence

& interaction of processes”, helps in building SIPOCs for all processes or

departments. It gives a basic idea in building activity, process, system &

procedure steps.

A foundry example is taken in the “Sequence & interaction of

processes” slide shown below. Seeing this one can have a broader idea about how

major processes or departments interact with each other. Activity & process

steps can be clubbed department-wise & we can use department concepts for

managing the processes better.

Marketing receives requirements from customers. Marketing forwards it to

“New product development” (called as “Mfg. process design” here) & this team

develops tools & equipment required for the product & conducts trials.

Production team takes over after trials & regular despatches starts. Based

on the product delivery & customer PPM levels, customer satisfaction is

measured & monitored continuously. QC, Purchasing, Stores, Machine

Maintenance, Tool Maintenance, HR, IT, Finance teams provide all the support

required for the successful production & despatch activities of products.

Top Management, MR & Internal audit team ensures all the practices comply

with requirements.

All the processes (or departments) are categorized as “Management

Processes (MP)”, “Customer Oriented Processes (COP)” & “Support Processes

(SP)” as shown in the image. Such categorization helps in prioritizing

processes like risk prioritization in FMEA. COP is first priority, SP is second

priority & MP is third priority. Owners need to concentrate in bringing

COPs to zero error levels first & other processes can be addressed after

that. It is also advisable to outsource partly or fully all the “Support

Processes” which helps the owners to concentrate in bringing zero error on

COPs. Many giant companies have already started outsourcing maintenance, qc, hr

activities. Some partial outsourcing activities are also possible in MP. Such

outsourcing also helps in cost reduction, audit man-days reduction by 3rd

party certification body auditors as their calculation of audit days depends on

head count of clients.

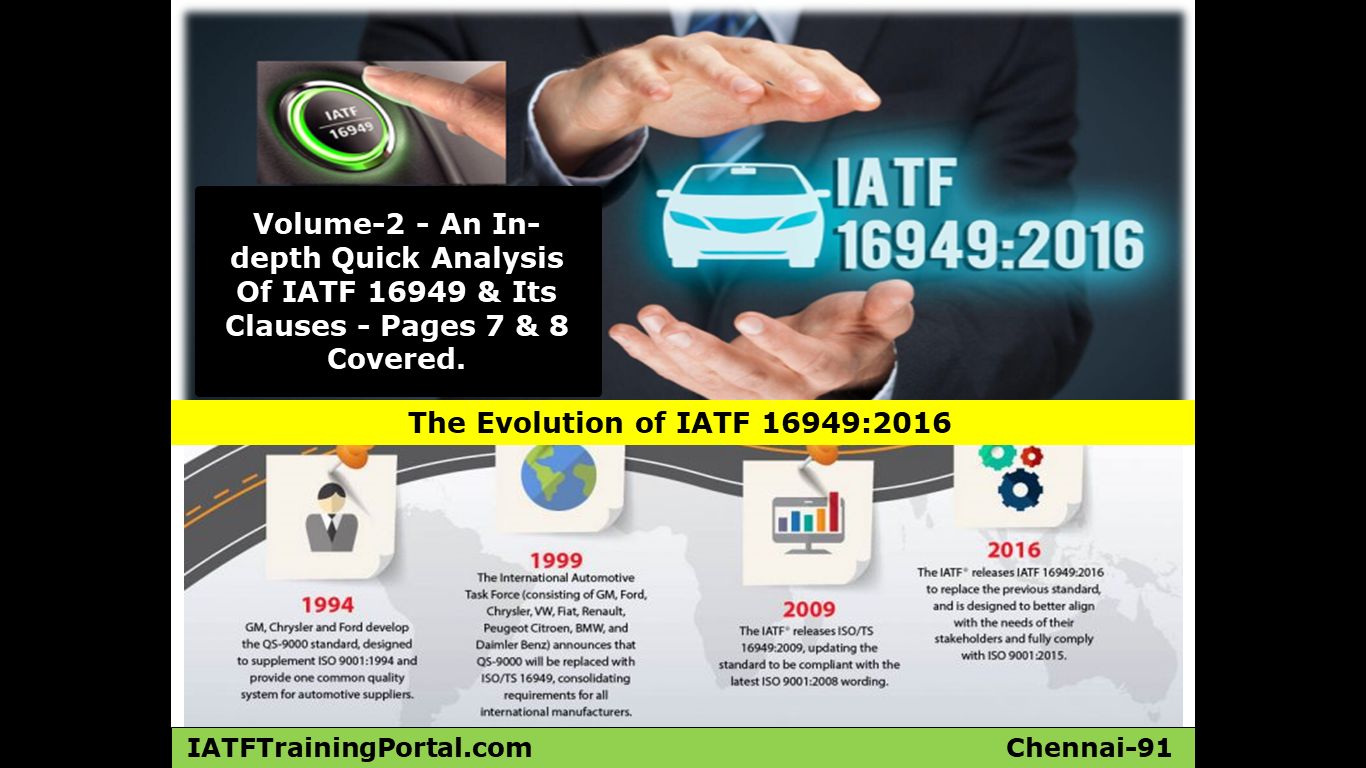

All the SIPOCs shared in this article were derived not only based on

IATF16949, but also considering the QMS requirements of IATF subscribing OEMs

like ASES of Renault Nissan, QSB of General Motors, 5 Star of Hyundai etc.

1) SIPOC Marketing

Let us start with the COP related SIPOCs first. Marketing comes first in

the business process flow mapping as well as in the COP. Seeing the SIPOC of

marketing will make you understand that it is not only a commercial activity,

there are lots of technical activities also involved. If any company or owner

is still seeing marketing as just a commercial activity, it is better to change

their mindset & bring techno commercial or technical persons into

marketing. This will definitely boost the confidence of customers &

internal team involved which will help in increasing sales, profits & productivity.

2) SIPOC Tool Design

Next SIPOC asper business process flow is “Tool design”. Once

commercials are freezed, the marketing team formally announces project

“kick-off” & releases the requirements to all the MP, COP & SP. The

next step is to start designing patterns, tools, core box, jigs, fixtures,

gauges. Tool design team derives a “Timing plan” for the release of designs

& adheres to the plan.

3) SIPOC Tool Manufacturing

Once design team starts releasing the drawings, “Tool manufacturing”

team derives a “Timing plan” for the manufacturing, assembly & trials to

prove the tools. “Tool manufacturing” team starts manufacturing the tools

in-house or outsources some of the tool manufacturing with the help of “process

engg” & “purchasing” team.

4) SIPOC Process Engineering

Process Engineering team derives a “Timing plan” in-line with “APQP”,

actively interacts with all the people involved from project kick-off till the

project handover (sign-off) to production after successful PPAP “Significant

production run”.

5) SIPOC PPC

PPC gets involved by scheduling trial orders by allocating resources

needed for trial runs. PPC increases the schedule gradually once the project

reaches PPAP run stage, ramp-up stage & full volume production stage.

6) SIPOC Sand Preparation

Casting production has 5 major steps: sand, core, moulding, melting

& fettling. Sand preparation is moulding sand preparation in tonnes of

volumes continuously to cater the moulding activities. Moulding sand prepared

is simultaneously checked by QC in the sand lab for 16 parameters for passing

the sand for further processing to the next process of moulding.

7) SIPOC Core Making

Cores are placed inside mould wherever holes, projections, grooves,

recess etc are required in a casting. A single mould or casting may require

multiple cores of various shape, size & core materials. Core shop will be

making such cores & transfer the same to the moulding section.

8) SIPOC Mould Making

Mould is made exactly like the shape of the final casting required with

some additional material that is unavoidable for the success of the process

like runners (to pour molten metal), risers (to ensure enough molten metal is

poured), parting lines etc. Modern mouds consist of only two half, the cope

& drag which is closed after moulding & placing cores in required

places. Moulds are moved on a JIT (Just In Time) conveyor or moved manually to

the next stage.

9) SIPOC Melting & Pouring

Melting happens in traditional style in cupola furnaces or in modern

electric furnaces. Tons of molten metal will be melted continuously & moved

to pouring machines or manual pouring sections. In pouring machines pouring

time can be automated & no need to watch runner riser constantly.

10) SIPOC Fettling

Runner risers & big projections are removed after pouring using

special tools. Casting is allowed to cool for several hours till it comes to

normal room temperature. Fettling is done to bring the casting to the final

shape. Snag grinding is done as a part of fettling to bring castings to the

exact size on the one or the three planes. Shot blasting is done to remove

unwanted sand or foreign particles from the surface.

11) SIPOC Pre-machining

Many casting defects surface when it is machined. Hence the latest

practice of all foundries is to do a pre-machining at their premises itself

which helps to avoid sending defective castings to customers. Pre-machining

brings the casting to the closest required shape & size, leaving only a few

finishing activities to be done by the customer prior to their assembly.

12) SIPOC Warehouse (Finished goods storage &

despatch)

Castings are moved to the warehouse from fettling or pre-machining. All

these castings are packed with adequate preservation with appropriate

identification & dispatched with necessary documents & reports to

customers.

Let us move on to the “Management Process” (MP) related SIPOCs

13) SIPOC Top Management

Top Management declares it Vision, Mission statements. Vision is the

final destiny or the final goal (Egs: World No.1 Foundry), it may take longer

time or even take generations to achieve this Vision. Mission are the next 5

year plan or progress intended which helps to achieve the vision on a longer

run. Vision derives mission & mission is converted into the business plan

for the present year. Top management monitors & ensures the business plan

goals for the year are met. Top Management reviews adequately with all the

process owners on a daily weekly monthly quarterly basis against business plans

& ensures recovery actions wherever the targets are not met.

14) SIPOC MR Functions

Management Representative ensures QMS practices are established,

implemented & maintained which guarantees the Top Management, Customers

& Process owners that the company, its processes & its products are at

its best all the time.

15) SIPOC Internal Audits

Internal audits can be a part of MR functions, or it can be taken care of by a separate team. QMSystem audit, mfg.process audit, product audit & many more audits that are happening more or less on a daily basis in some companies has raised the need to have separate team or atleast one dedicated person with some part time auditors from other processes to handle “Internal Audit” process separately.

Let us move on to the “Support Process” (MP) related SIPOCs

16) SIPOC Purchasing

Mostly purchasing decides make or buy decision. Latest profitable trend

is to make 40% or less & buy 60% or more. This helps to multiply turnover

also without increasing capital expenditure. Making important manufacturing

& assembly activities in-house & buying rest is a successful purchasing

strategy.

17) SIPOC Stores

Storing as little as possible is the trend. Even storing nearer to the

consumption point inside the shop floor is also a viable solution. Smaller

stores help in increasing the profitability.

18) SIPOC Infrastructure

Infrastructure department constructs new buildings, new machines, new

conveyor systems, maintains roads, canteens, electrical, plumbing activities

across the plant.

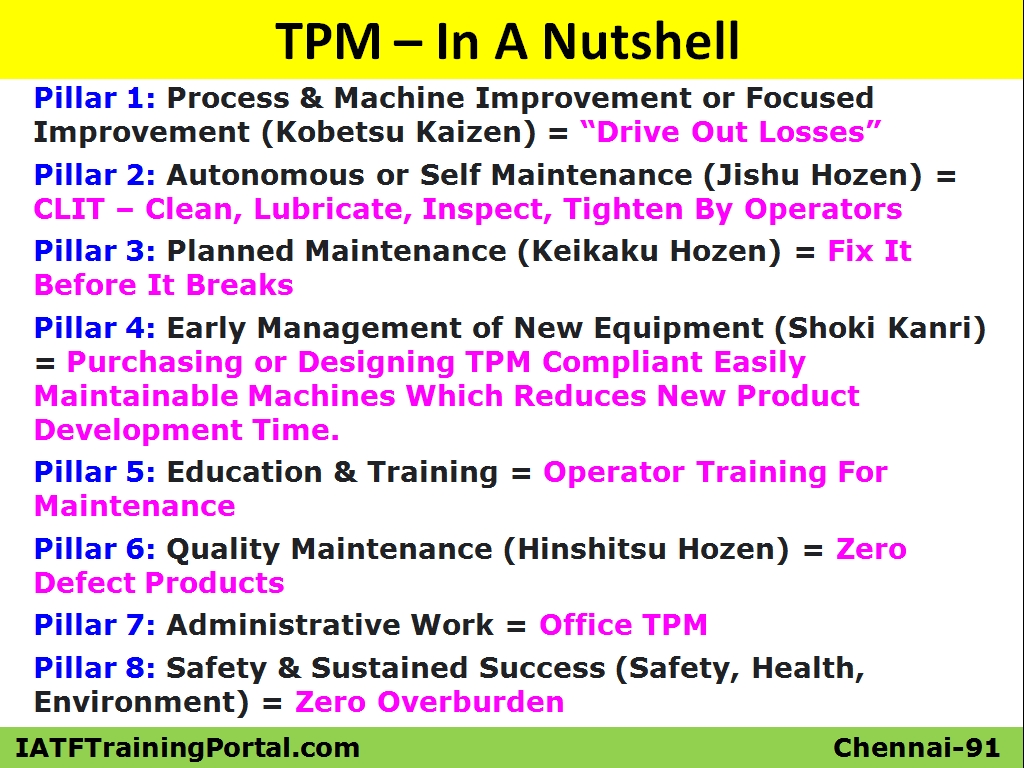

19) SIPOC Machine Maintenance

Manufacturing industries need to concentrate on machines to bring zero

defects. Hence this function is vital. Machine maintenance takes over

infrastructure built including machines from the infrastructure department

& maintains it. MTBF & MTTR are two vital process indicators that need

to be monitored, measured & improved continuously. TPM also helps in

bringing zero breakdowns as well as trains machine operators to do regular

& minor maintenance activities. This helps production to be less dependent

on the machine maintenance team to run the show 24x7 without any hiccups.

20) SIPOC Tool Maintenance

Tool maintenance is an important function for any foundry or for any

tool dominant processes like sheet metal, plastic injection moulding, thermo-coal

manufacturing units. Foundry activities by its nature have to handle too much

equipment like core boxes, patterns, jigs, fixtures that need regular

servicing, replacement, repair & calibration. Hence it needs a separate

team to handle these activities. In other cases, the machine maintenance team

& production team can handle the maintenance of equipment also apart from

machines.

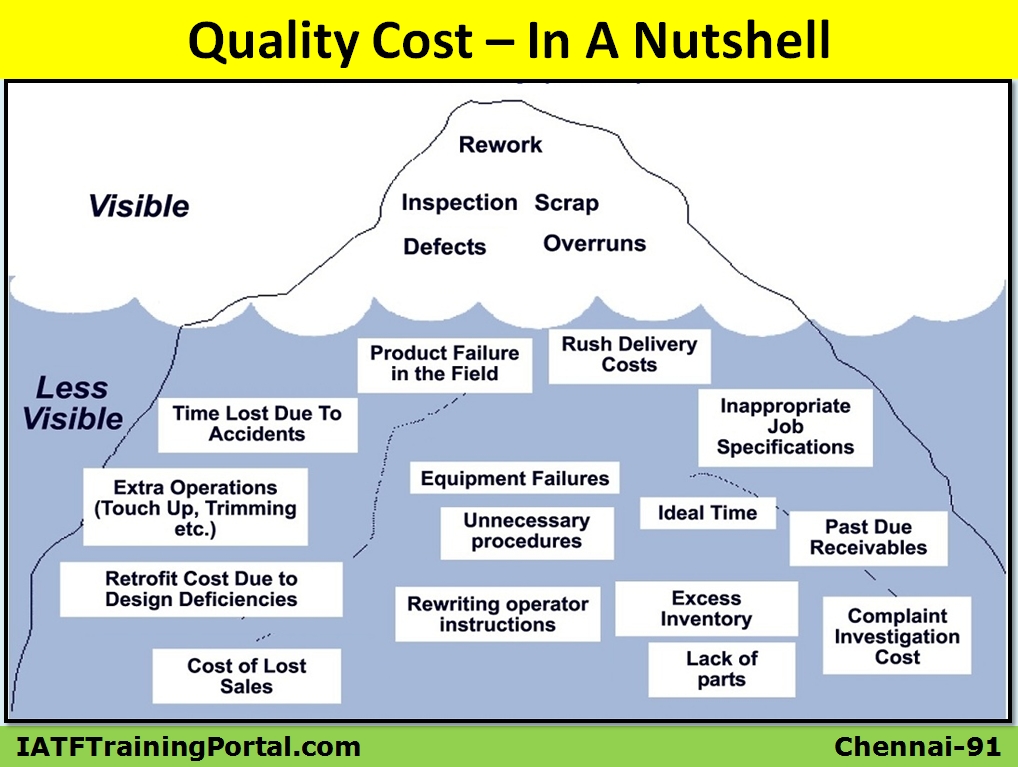

21) SIPOC Quality Control

Quality control’s job is detection, prevention (QA) is inbuilt into the

NPD process. QC through their incoming, inprocess, final inspection activities

will keep on detecting NC products. Production & NPD must challenge &

encourage QC to try & find NC products. QC will also maintain internal

labs, do calibration & MSA activities apart from inspection.

22) SIPOC Human Resource

HR takes care of employee life cycle during their tenure with the

company, i.e, from joining till resignation. HR also takes care of training of

supervisors & above. Actually the training indicated in IATF or ASES or QSB

insist on adequate training to those who are actually involved in producing

products like operators & casual labourers. Training supervisors &

above do not bring any huge impact on product or process, hence such training

can be limited. More focus needs to be given to training operators & casual

labours. In the SIPOC of production (sand, core, moulding, melting, fettling,

pre-machining) provided above, one can see more focus is given to operator

& casual labour training. Four separate procedures (1)operator training

(2)operator observation (3)refreshment training for operators (4)casual labour

training were assigned to the production department. As these training are too

technical, it is assigned to the production department & they are asked to

take care of these meticulously.

23) SIPOC – Information Technology

The role of IT in a foundry or any factory has a very limited role yet

it is very powerful. They may not be deciding on technical software to be

purchased like Autocad, Catia, software for QMS but their role is vital in

maintaining this software & ensuring no data loss or data theft happens.

Thanks for spending your valuable time here. Keep in touch, keep

following & keep supporting us.

Thanks & Regards,

Devarajan NR,

Chairman – JBEGlobal.com Job Portal

& IATFTrainingPortal.com (Since 2013) Past – Delphi TVS | Rane | Brakes

India | Iris Mfg. (Shriram Group) | Hinduja Foundries | IRS (IRQS) | 9362439124

| devarajan.jupiter@gmail.com