Cover page

The cover page contains the following information,

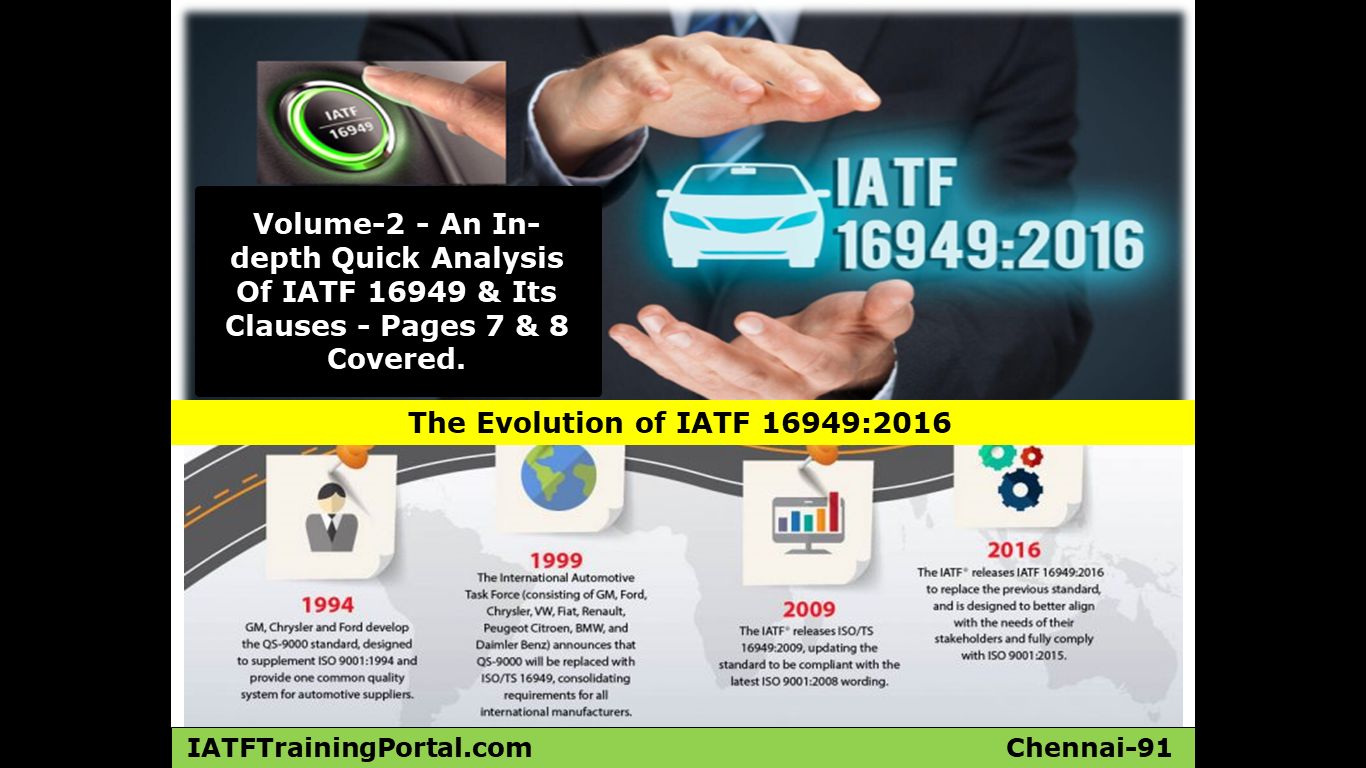

1) Automotive Quality Management System Standard

This states that this is a “QMS” standard for automotive industry. You can also consider this as a short description for this standard.

2) IATF 16949

This is the alphanumerical title for the standard. In this IATF stands for “International Automotive Task Force” & 16949 is a unique number allotted to this standard.

3) Quality management system requirements for automotive production & relevant service parts organizations

This can be considered as the long description for the standard. Long description quotes this standard has QMS requirements for automotive production & relevant service parts organization.

4) IATF logo

IATF logo is printed as IATF own the rights for this standard.

5) 1st Edition. 1 October 2016

This is the 1st edition for this standard & this 1st edition was released on 01-Oct-2016

6) IATF copyright notice

Copyright of this standard is held by IATF members. Reproducing, storing as electronic, photocopy, recording or otherwise is prohibited. Requests for reproducing or translation can be addressed to ANFIA/Italy, AIAG/USA, FIEV/France, SMMT/UK, VDA/Germany.

Table of contents

From here the standard starts numbering of pages. “Table of contents starts with page number 1 & runs through page number 6. First six pages are dedicated to explain the contents of this 58 page standard. To simply understand the table of contents, we can see how many clauses are listed as below,

· 7 Level-1 clauses (Egs: 7)

· 28 Level-2 clauses (Egs: 7.5)

· 72 Level-3 clauses (Egs: 7.5.3)

· 75 Level-4 clauses (Egs: 7.5.3.2)

· 12 Level-5 clauses (Egs: 7.5.3.2.1)

The 7 level-1 clause titles are,

1) Clause 4 – Context of the organization

This clause covers understanding the organization, needs & expectations of the interested parties, scope (boundary) of the QMS, customer specific requirements (CSR), QMS processes.

2) Clause 5 – Leadership

This clause covers commitment, corporate responsibility, process effectiveness & efficiency, process owners, quality policy, roles, responsibilities & authorities.

3) Clause 6 – Planning

This clause covers risk analysis, preventive action, contingency plans, quality objectives, managing change to qms.

4) Clause 7 – Support

This clause covers resources (6M), people, infrastructure, environment, monitoring & measuring, MSA, calibration, labs, competence, awareness, motivation & empowerment, qms documentation, control of documents, records, engineering specifications.

5) Clause 8 – Operation

Clause 8.1 & 8.2 covers planning & control of manufacturing processes, customer communication, product & service requirements, special characteristics, manufacturing feasibility, managing changes to products & services.

Clause 8.3 covers design & development planning, inputs, controls, outputs & change management during design & development

Clause 8.4 covers supplier selection, customer approved suppliers, supplier control, supplier qms, supplier monitoring, supplier audits (2nd party), supplier development.

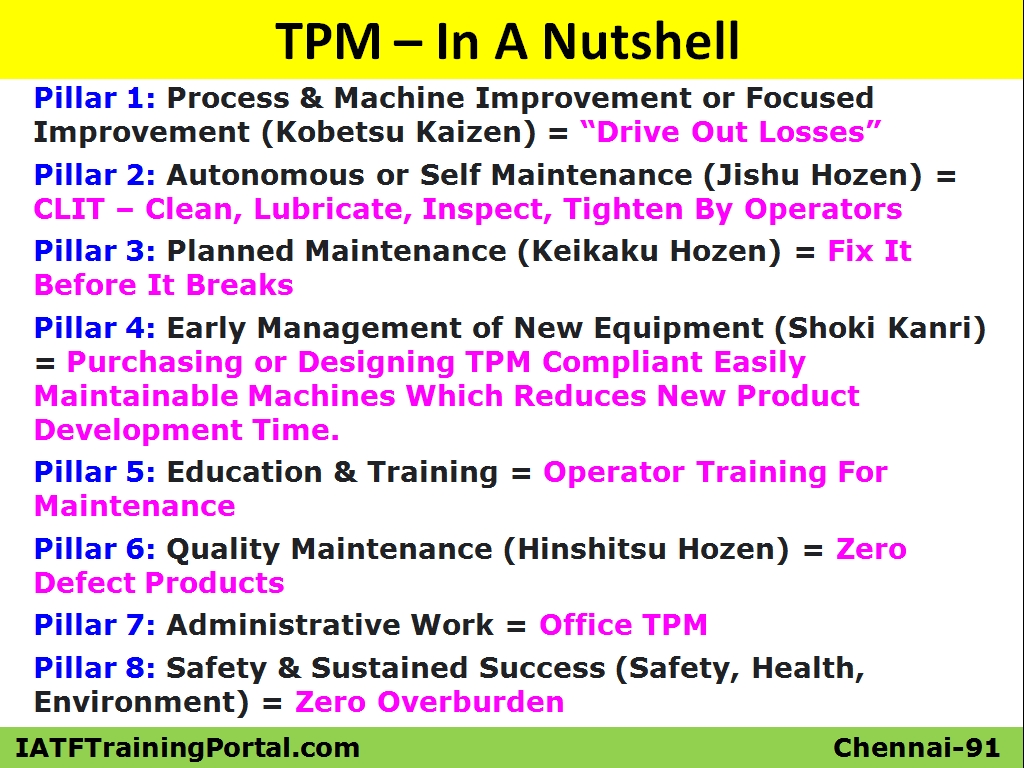

Clause 8.5 covers production & service provisions, control plan, operator instructions, visual standards, job set-ups, shut down verification, TPM, production tools management, production scheduling, identification & traceability, customer property, preservation, post delivery, change management.

Clause 8.6 covers product release, layout inspection & functional testing, incoming inspection, appearance items, statutory & regulatory conformity of supplier products, acceptance criteria

Clause 8.7 covers control of non-conforming products, concession, suspect, rework, repair, disposition & customer notification, customer specific nc management.

6) Clause 9 – Performance evaluation

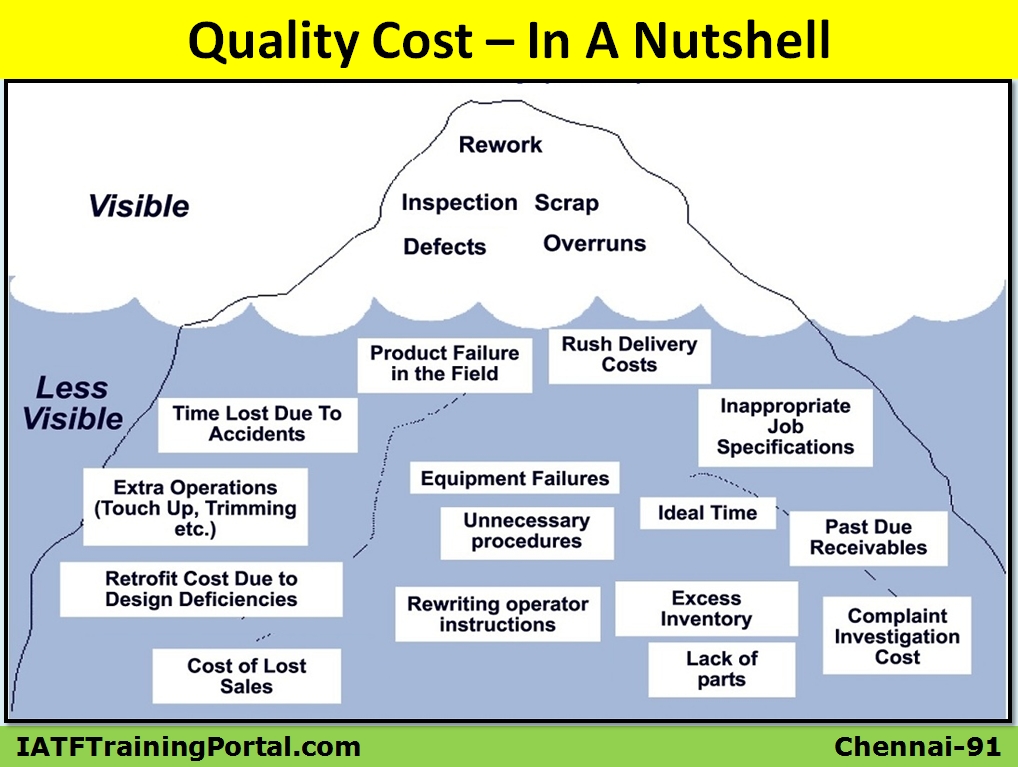

Clause 9.1 covers monitoring, measurement, analysis & evaluation of qms & manufacturing processes, identifying appropriate statistical tools & application, customer satisfaction, prioritization of actions.

Clause 9.2 covers internal audits, qms audits, manufacturing process audits & product audits.

Clause 9.3 covers management review, input & outputs of management review.

7) Clause 10 – Improvement

This clause covers improvement of processes, products, services & qms, non-conformity & corrective action, problem solving, error proofing, warranty management, customer complaints, field failure test analysis & continual improvement.

Keep following our website for more volumes on this topic “An in-depth quick analysis of IATF 16949 & its clauses”.

Thanks for spending your valuable time here. Keep in touch, keep following & keep supporting us.

Thanks & Regards,

Devarajan NR,

Chairman – JBEGlobal.com Job Portal & IATFTrainingPortal.com (Since 2013) Past – Delphi TVS | Rane | Brakes India |

Iris Mfg. (Shriram Group) | Hinduja Foundries | IRS (IRQS) | 9362439124 | devarajan.jupiter@gmail.com