While preparing for VSM, it is important to map your business processes.

Any business process starts with reaching potential customers seeking orders.

Keeping this as the first step or whatever you do as your 1st process

step, keep on asking what next & build a pakka business map. While drafting

your business process map it is advisable to do it in a 5W-2H methodology, a

sample is attached below. 5W-2H means What, Who, When, Why, Where, How, How

many. For every process step it is better to define

·

What

is to be done?

·

Who

will do it?

·

When

it has to be done?

·

Why

does it have to be done?

·

Where

it has to be done?

·

How

it has to be done? If this needs to be elaborated further, a suitable work

instruction can be referred to.

·

How

many refers to quantity or frequency for performing the activity repeatedly

Once this is done, the owners will be having a broader perspective of their business & the entire team involved also will have a better idea about upstream & downstream business processes to drill deep further into VSM.

VSM is quite a broader subject, hence unable to bring it in a single

slide & covered the essence in 3 slides.

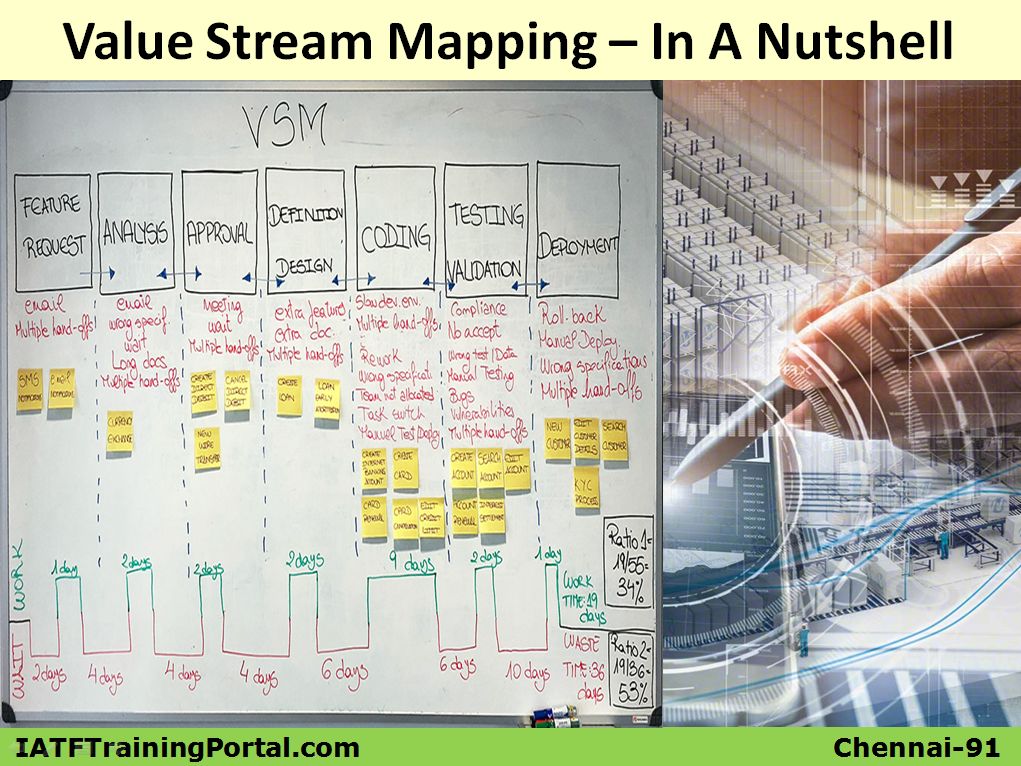

VSM – In A Nutshell – Slide-1

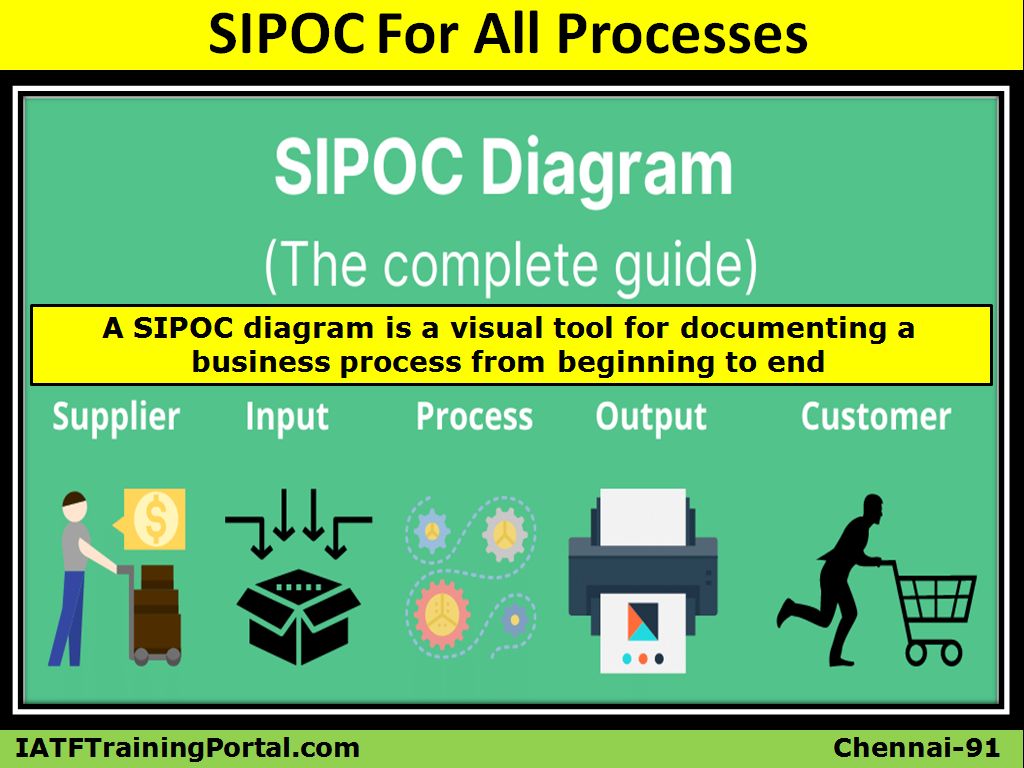

Business process mapping can have macro level & micro level process

maps. Macro level is called high level process map & micro level process

map are called sub level process map. VSM Slide-1 shows such a high level &

sub process map of a purchasing process where the team purchases vegetables,

fruits, beverages etc., required for a restaurant kitchen for further

processing (cooking). High level process map covers SIPOC also; SIPOC means

Supplier, Input, Process, Output, Customer. SIPOC shown here is a very simple

one, see our “SIPOC – For All Processes” articles to understand how to build

the best SIPOC charts.

VSM Slide 1 gives clarity about process steps involved in the “Food

Order Delivery” Process. This process has six macro level (or high level)

process steps,

1) Contact supplier(s)

2) Negotiate order

3) Place order

4) Schedule delivery

5) Track delivery

6) Delivery occurs

From these six steps the owner with his team chooses 2) Negotiate order

as a significant one in this process & decides to drill deep into this

process. Team is developing a micro (or sub) level process map for the 2)

Negotiate order that contains nine process steps,

1) Request bid (RFQ) from approved suppliers

2) Wait for quote via fax / email

3) Review quotes submitted

4) Contact finalized list of suppliers

5) Renegotiate

6) Go to alternate suppliers

7) Wait for final submission

8) Award weekly contracts

9) Contact vendor

VSM – In A Nutshell – Slide-2

This slide explains very clearly why it is called “Value Stream

Mapping”. Value is the time or money (time is money) associated with each step.

Stream refers to the process steps. Mapping these to the required downstream or

upstream level process steps gives a clear idea about how to improve upon

further. This slide clearly explains the time taken for the nine activities for

the high level process step 2) Negotiate order

VSM – In A Nutshell – Slide-3

Now we are ready to categorize the process steps into VA / NVA (Value

added / Non Value Added) activities. A process step is considered as a value

added activity if it satisfies the following three criteria,

1) Work that the customer is willing to pay for.

2) Work that physically transforms the product.

3) Work that is done right the first time.

Using the above 3 criteria, the team identifies 4/9 activities as NVA

& 5/9 as VA. The total time taken for the above nine process steps can be

reduced from 168+28=196 hrs to 28hrs if the NVAs are removed from the process

steps successfully.

Following four ideas can be tried to get rid of NVA activities,

1) Delete it / Stop doing it.

2) Automate it / Reduce it.

3) Merge it with other activities.

4) Delegate it / Outsource it (if not part of the core value)

Let us take the four NVA identified in the example seen by us in VSM

Slide-3 & think of some possible solutions,

2) Wait for quote via fax / email

5) Renegotiate

6) Go to alternate suppliers

7) Wait for final submission

2) Wait for quote via fax / email

Modern trend is to send drawings via supplier portal with time limits

set to submit quotes. This avoids waiting time drastically.

5) Renegotiate

Work out costing & fix a target price & communicate the target

price along-with RFQ (Request for quotation). All suppliers will quote nearer

to the target price. Choose the best based on the cost, past history on

quality, delivery & response of the suppliers.

6) Go to alternate suppliers & 7) Wait for final submission

Reach all potential suppliers at a time with a timeline to submit quotes

& budget prices.

Thanks for spending your valuable time here. Keep in touch, keep

following & keep supporting us.

Thanks & Regards,

Devarajan NR,

Chairman – JBEGlobal.com Job

Portal & IATFTrainingPortal.com (Since 2013) Past – Delphi TVS | Rane | Brakes

India | Iris Mfg. (Shriram Group) | Hinduja Foundries | IRS (IRQS) | 9362439124

| devarajan.jupiter@gmail.com